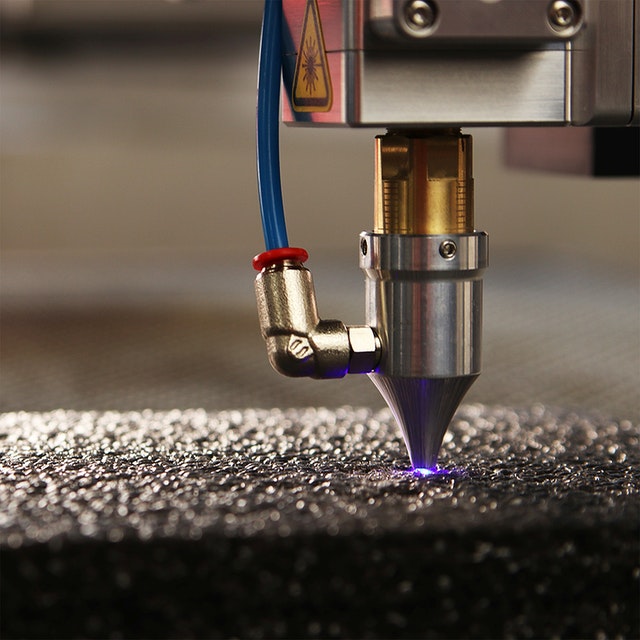

Are you thinking about purchasing a laser cutting machine? You should know that you will require a specific type of laser cutting machine based on the materials you wish to cut or engrave. A CO2 device is needed for things like glass, leather or wood but you will need a fibre beam if you wish to work on metals or polymers. A beam that contains both CO2 and fibre in a single machine, making it the best choice if you wish to accomplish both.

When shopping for a laser cutting machine, what should I look for?

What you intend to utilise the device for will play a large role in your decision.

Investing in a laser cutting machine requires careful consideration of several variables, including:

- What kinds of materials are you planning to process?

- How big are your projects?

- In what thicknesses are you looking to cut and how quickly do you want to engrave?

- How important is it to you that your machines work properly?

Read our breakdown of these considerations below;

The size of your work area

The size of your work area will determine the size of your finished products.

The size of your laser cutting machine

The size of the device depends on the overall size of the workpieces to be engraved or cut. It’s also a good idea to think about how many pieces of work you want to do at once, as doing so in one pass will increase productivity and boost your output.

Power of beam

Greater adaptability is provided by higher power. You should keep in mind that the applications you’d like to use your laser cutting machine for will determine how much power it needs before making a final decision on its power. To get good results with a device for engraving, you just need 30 to 80 watts of power. However, we recommend beam powers more than 80 watts for routine material cutting and high-speed engraving. Having just the proper amount of power is critical to getting the optimum results from heat treatment. For example, engrave paper with less power than engrave woods with greater strength. To achieve a uniformly homogenous and not excessively deep engraving on acrylic, a low power device is all that is required. However, when working with plastic laminate materials increased power allows you to do your work much more rapidly.

It is possible to control the power of the beam from within the programme, however the maximum amount of power is limited by the hardware. As a general guideline, remember this: Because it can handle a wider range of materials, a high-power piece of equipment provides greater flexibility.

Reliability

The most important factors when purchasing a laser cutting machine are dependability and high quality of service. The reliability of the laser cutting machine you choose will have a significant impact on the success of your business, since only a fully operating equipment can provide your clients with consistent reliability and repeatability. It is critical that you choose a machine that is both reliable and easy to use, with outstanding customer support and readily available spare parts, when deciding which device to buy.

What kind of laser cutting machine should you use for a business?

Prices, product quality, and customer service would all be drastically different. Basic laser cutting machines can cut and engrave, but the range extends all the way up to highly specialised and sophisticated production equipment that are geared towards maximising the efficiency of the end-user. However, the most crucial consideration to keep in mind when selecting a laser cutting machine is the intended purpose and the desired application result.